Location:

Home >

Molded Pulp Cup Lid

Location:

Home >

Molded Pulp Cup Lid

Location:

Home >

Molded Pulp Cup Lid

Location:

Home >

Molded Pulp Cup Lid

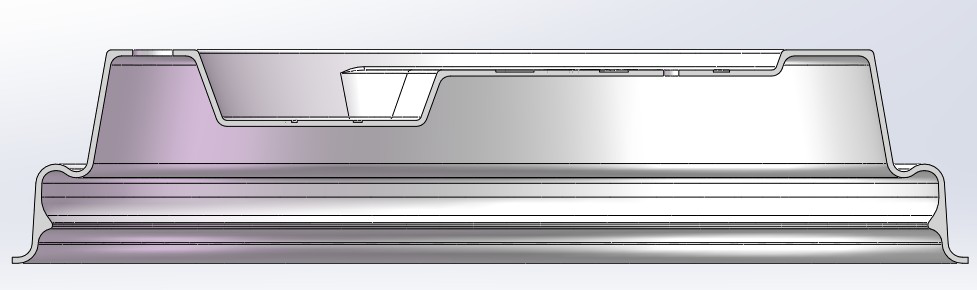

Molded Pulp Cup Lid

The fully automatic production line of "molded pulp (fiber) cup lid - paper cup lid with inverted buckle" developed by EAMC is more advanced and competitive. No need secondary processing, one-time forming "cold and hot drink cup lid with inverted buckle".

EAMC’s cold and hot drink paper cup lid with inverted buckle has obtained the national patent, and the lid has an excellent lock effect on the paper cup. Paper cup lid - molded pulp (fiber) cup lid is an environmentally friendly and degradable product.

EAMC has filed a patent for "a molded fibre cup lid with an inner convex ring" and has obtained a patent certificate.

Patent molded fibre cup lid with an inner convex ring (inverted buckle), described as follows:

Technical Field

The present patent relates to a cup lid or box lid made of a plant fiber molding method. Disposable biodegradable molded plant fiber cup lids or box covers are hereinafter referred to as molded fiber (pulp) cup lids, may be round, square or various other shapes.

Description of Related Art

Traditional plastic cup lids do not degrade and can cause white pollution to the environment. So molded fiber (pulp) cup lids are needed to replace the plastic cup lids.

The production process of molded fiber products is:

Plant fiber in the suck-filter forming molds first through suck-filter forming, made into wet blank (wet semifinished products). The wet blank (wet semifinished products) is sent into the heating molds heated to a certain temperature, clamp the hot pressure mold and dry the wet blank, to make the molded fiber (pulp) cup lids products of various shapes. The inner convex ring of the cup lids is directly squeezed inward by the wet blank of the cup lids during the hot pressure forming process (hot press mold solidifing).

Function

The inner convex ring of the cup lid is actually a "inverted buckle", its effect : "barb" the cup lid on the "ring rim" of the cup, play the" inverted buckle " effect.

The cup mouth edge of the paper cup is a ring structure, simply the "ring mouth edge". An "arc ring" is also required to be set on the cup lid, coming in close contact with the "ring mouth edge" of the paper cup to prevent liquid outflow; while preventing the cup lid from falling off when the cup falls, and set a "barb" on the cup lid from getting loose from the cup. This "barb" is the inner convex ring of the cup lid, which acts to "barb" the lid on the " ring mouth edge of the cup. Play a "reverse buckle" role, and the cup lid does not easily fall off the cup when the cup is dumped.

The technical scheme for a cup lid with an internal convex ring is:

An inner convex ring is positioned on the inner side of the cup lid with smooth without dents on the outer side of the cup lid. The inner convex ring can jam the paper cup "ring mouth edge" to prevent the "ring mouth edge" of the cup from slipping out of the "curved groove" of the cup lid. In the process of hot pressing the wet blank of the cup lid into a dry and shaped cup lid, the inner convex ring is directly squeezed in the process of hot pressure forming, without a second processing; Because the height of the inner convex ring is not large, the resistance is not large when the cup lid is detached from the hot pressure die; the removal can be forced to pull the cup lid stuck from the hot pressure die to complete the removal of the cup lid.

The beneficial effects of molded fiber (pulp) cup lids with inner convex rings are:

Under the premise of keeping smooth on the outer side of the cup lid, an inner convex ring is set at the appropriate position of the inner side of the cup lid, so as to realize the disposable molding of the plant fiber molding cup lid, and avoid the complex link of the plant fiber molding products after molding;

Such a cup lid structure, good sealing effect and can jam the cup mouth to prevent shedding;

It not only ensures the sealing effect, but also reduces the production link of molded fiber (pulp) cup lids, which provides convenience for automatic production, and more importantly, to ensure that the appearance of molded fiber (pulp) cup lid is not damaged.