Materials

Materials

We proudly provide advanced plant-fibre molding equipment and manufacturing solutions

Raw material sources:

Making pulp process:from plant fiber to pulp(pulp making produciton line)

Preparation pulps:from pulp sheet or wet pulp to final products(by pulp molding facotry)

Pulp Molding Raw Material 1: Bagasse Pulp

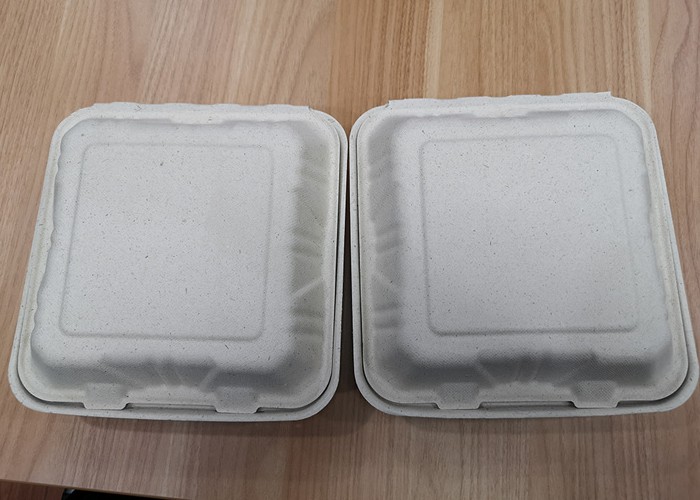

Bagasse pulp is a good raw material for pulp molding products. Production of pulp molding dining box tableware products using bagasse fiber.

Bagasse pulp made of bagasse, after chemical or biological. Bagasse pulp may be wet or dried and pressed into a pulp board. The wet bagasse pulp adds water, configured to provide a certain concentration of pulp for pulp molding production directly. The pulp board should be broken by the pulp crusher and then added water to form a certain concentration of paper pulp for pulp molding production. Paper pulp is molded, shaped and cut into molding products in pulp molding machine.

Bagasse fiber is medium and long fiber, which has the advantages of moderate strength and toughness, and is the most suitable raw material for molding products at present, so bagasse pulp products are the most widely used at present. At present, bagasse fiber is used in tableware products, and some high-end mobile phone support, cosmetics packaging also use this raw material.

Bagasse pulp is produced all over the world, Southeast Asia such as Thailand, America such as Colombia, Mexico, Brazil, the Middle East such as Iran, China's Guangxi, Yunnan and other places.Sugar cane is heavily planted in these areas, and there are many sugarcane factories, which is the raw material of sugarcane mills, which was originally the waste of sugarcane factories, but many sugarcane factories have established sugarcane pulp mills to supply pulp to paper mills and pulp molding mills. With the development of pulp molding technology and market, the industrial chain of many bagasse pulp mills began to extend to molded pulp products, and they purchased pulp molding machines to establish pulp molding products factories.

bagasse

bagasse pulp products

bagasse pulp products

bagasse pulp products

Pulp Molding Raw Material 2: Bamboo Pulp

Bamboo pulp is a very good pulp molding (plant fiber mold) products raw materials. Bamboo fiber belongs to medium and long fiber and its properties are between coniferous wood (needlebush) and broad-leaved wood.

The products produced by bamboo pulp has strong toughness, it is not easy to crack when producing deep products, the surface is smooth and delicate, and the whiteness is high. But when the surface of the product is rubbed, it is easy to appear fluffy fibers. When the proportion of bamboo pulp is more than 40%, the pulp should be ground to eliminate the appearance of fluff fiber on the surface of the product.

Bamboo pulp is mostly used to make high-grade mobile phone packaging, cosmetics packaging, but also used to make tableware, is a good pulp molding raw materials. A certain proportion of bamboo pulp is generally needed to produce products with complex shapes, small slopes and R angles. Because bamboo pulp resources are more valuable and the price is slightly higher than bagasse pulp, it is mostly used in proportion with bagasse fiber to increase performance and reduce cost.

Bamboo pulp in the south of China, Sichuan and Jiangxi.

bamboo

bamboo pulp poducts

bamboo pulp poducts

bamboo pulp poducts

Pulp Molding Raw Material 3: Wheat Straw Pulp

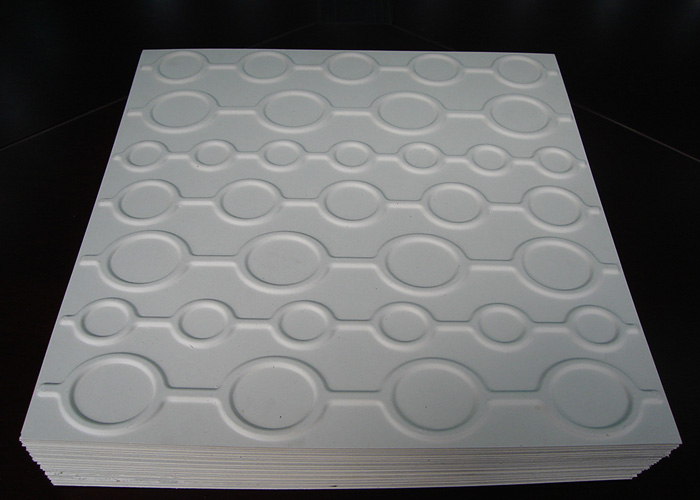

Wheat straw pulp, divided into mechanism fiber wheat pulp, chemical mechanical wheat pulp and chemical wheat pulp.

Wheat straw pulp fiber is short, molded wheat straw fiber products surface smooth and delicate, good stiffness, the product is very brittle, poor flexibility, most pulp molding tableware products can be 100% wheat straw pulp as raw materials. However, for molded wheat straw fiber products with complex shape and deep depth, it is necessary to add long fiber pulp to the production process to increase the toughness of the products.

Wheat straw pulp is mostly primary color pulp. bleached wheat straw pulp is less seen in the market. Wheat straw pulp mostly appeared in Shandong Province and northern China. Because the wheat planting area is very large in the world, especially in the north of China, a large number of wheat straw can not be treated, so the production of wheat straw pulp has a broad prospect, but the pulp yield of wheat straw pulp is relatively low.

wheat

wheat pulp products

wheat pulp products

wheat pulp products

Pulp Molding Raw Material 4: Reed Pulp

Reed pulp, mainly chemical reed pulp and chemical mechanical reed pulp.

Reed pulp fiber is short, Reed pulp paper pulp molding products surface smoothness is not as bagasse pulp, bamboo pulp, wheat straw pulp molding products; stiffness is general, also inferior to bagasse pulp, bamboo pulp, wheat straw pulp; Reed pulp molding products are more brittle, poor flexibility; Reed pulp contains more impurities. Most pulp molded tableware products can use 100% Reed pulp as raw material. Reed pulp products appearance is not very smooth and beautiful and more impurities.

However, for reed pulp products with complex shape and deep depth, it is necessary to add long fiber pulp to the production process to increase the toughness and surface appreciation of the products.

Reed pulp appeared in Jiangsu, Zhejiang, Shandong and Xinjiang provinces. Especially there are a large number of Reed output near the estuary of the Yangtze River in China, so the production of Reed is rich in resources, and the pulp yield of Reed is also relatively low.

reed

reed pulp products

reed pulp products

reed pulp products

Pulp Molding Raw Material 5: palm pulp

Palm pulp is also a good raw material for molded pulp products. Palm pulp is mostly the true color (original color) pulp.

The palm oil factory extracts the remaining palm fiber to produce palm pulp, and then uses palm pulp to produce molded pulp products. Molded palm fiber products have beautiful appearance, good stiffness and natural plant fiber color.The length of palm fiber is close to that of wheat straw fiber, but the pulp yield is higher than that of wheat straw pulp. Although there are many impurities in palm pulp, these impurities are also plant fibers, so molded palm fiber products look beautiful, natural and environmentally friendly.

Palm oil plants are very large in Southeast Asia. As early as 2, 000 years ago, the Malaysian government introduced an incentive policy for the comprehensive utilization of the palm fiber to encourage enterprises to further develop and use the palm fruit fiber.

A team of ECOPACK companies from Malaysia worked with Hangzhou Zheng Tianbo to study the comprehensive utilization of palm fiber in 2004. In 2005, the world's first molded palm fiber products were manufactured in Malaysia and awarded by the Malaysian government.

Some non-pulp companies in Malaysia and Indonesia are preparing to invest in palm pulp projects, but palm pulp plants invest heavily in wastewater treatment, due to insufficient funds for palm pulp plants. So the current supply of palm pulp is not much, palm fiber molding products rarely appear on the market.

palm

palm fiber

palm pulp products

palm pulp products

Pulp Molding Raw Material 6: wood pulp

Wood pulp is also a raw material for pulp molding products.

Wood pulp is mainly divided into coniferous wood pulp and broad-leaved wood pulp. The wood pulp used to produce molded pulp products is generally used in combination with leaf wood pulp and broad-leaved wood pulp, each accounting for a certain proportion.

Coniferous wood pulp fiber long and fine, wood pulp is relatively pure, less impurities.

The broad-leaved wood pulp fiber is thick and short, and contains more impurities.

The strength of the finished product is relatively low, the finished product is relatively loose, the absorption performance is strong, and the opacity is high. The pulp molded products made of coniferous wood pulp have good flexibility, high folding resistance and good tensile strength.

The pulp molded products made of broad-leaved wood pulp have high loose thickness, high stiffness and good packaging performance.

Therefore, the thickness and density of different wood pulp products will be different.

According to the above properties and the use of pulp molding products, the matching ratio of leaf wood pulp and broad-leaved wood pulp was determined.