From 14 to 16 July, 2021 China Packaging Container Exhibition was held in Shanghai New International Expo Center. iPackCon China Packaging Container Exhibition is a professional full variety of packaging container professional display platform, focusing on displaying packaging containers of paper, plastic, metal, glass materials, innovative packaging design, packaging development trend and overall packaging solutions. With the international and domestic plastic ban work to advance, Fully natural degradation of molded plant fiber products in the field of packaging has a prominent status. Participating in the exhibition are domestic molded fiber products manufacturers,pulp molding machine and equipment manufacturers, adjuvant suppliers.

domestic molded fiber products manufacturers including domestic fiber products manufacturers,biodegradable molded pulp tableware manufacturers, molded pulp packaging manufacturers, molded fiber (pulp) tray/ plate manufacturers,molded pulp industrial packages manufacturers,molded pulpcup lid manufacturers, molded pulp packing manufacturers,molded pulpcontainers manufacturers.

Pulp molding machine manufacturers including full automatic pulp molding tableware machine,fully automatic molded pulp cake carrier production line.

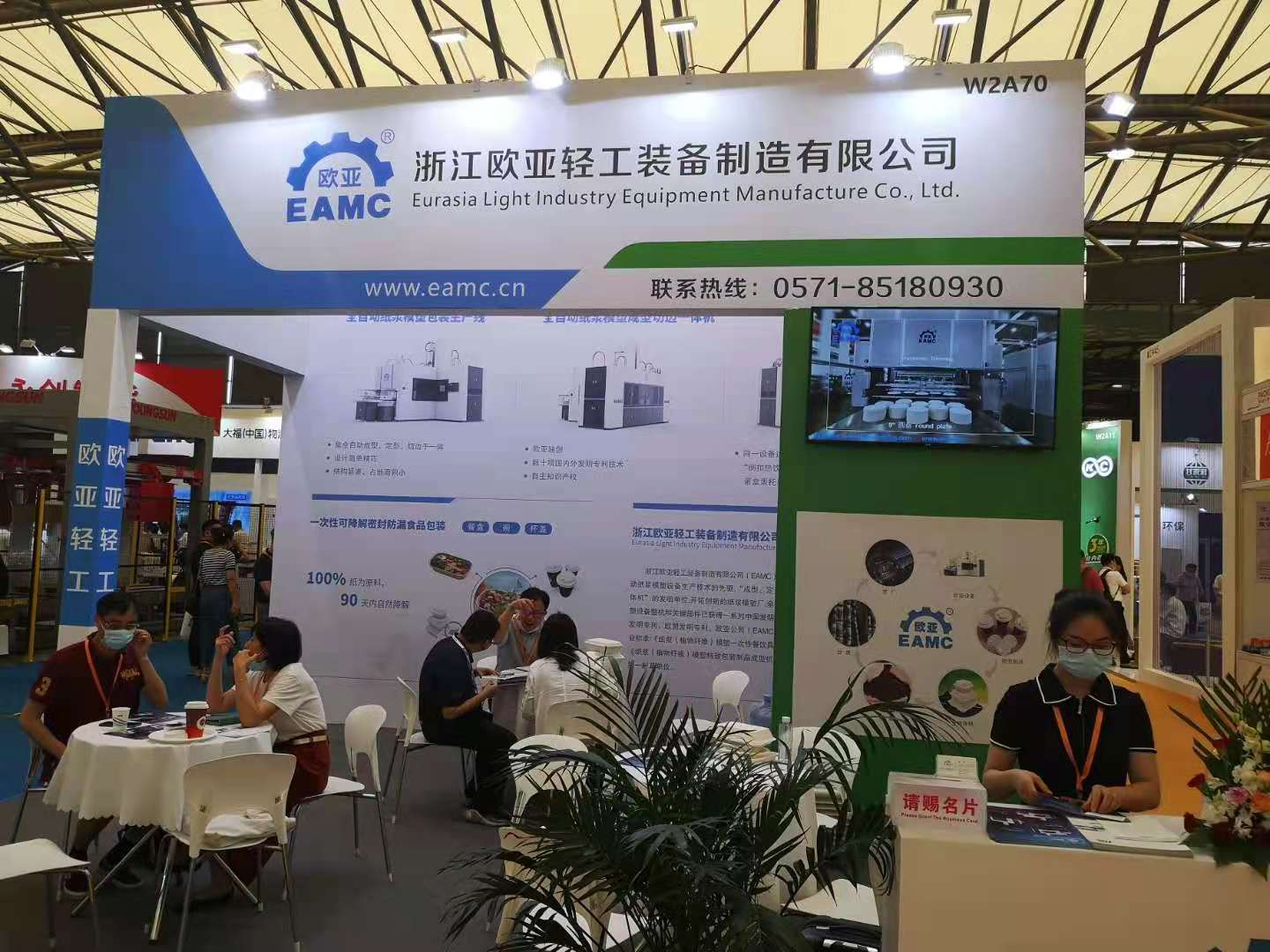

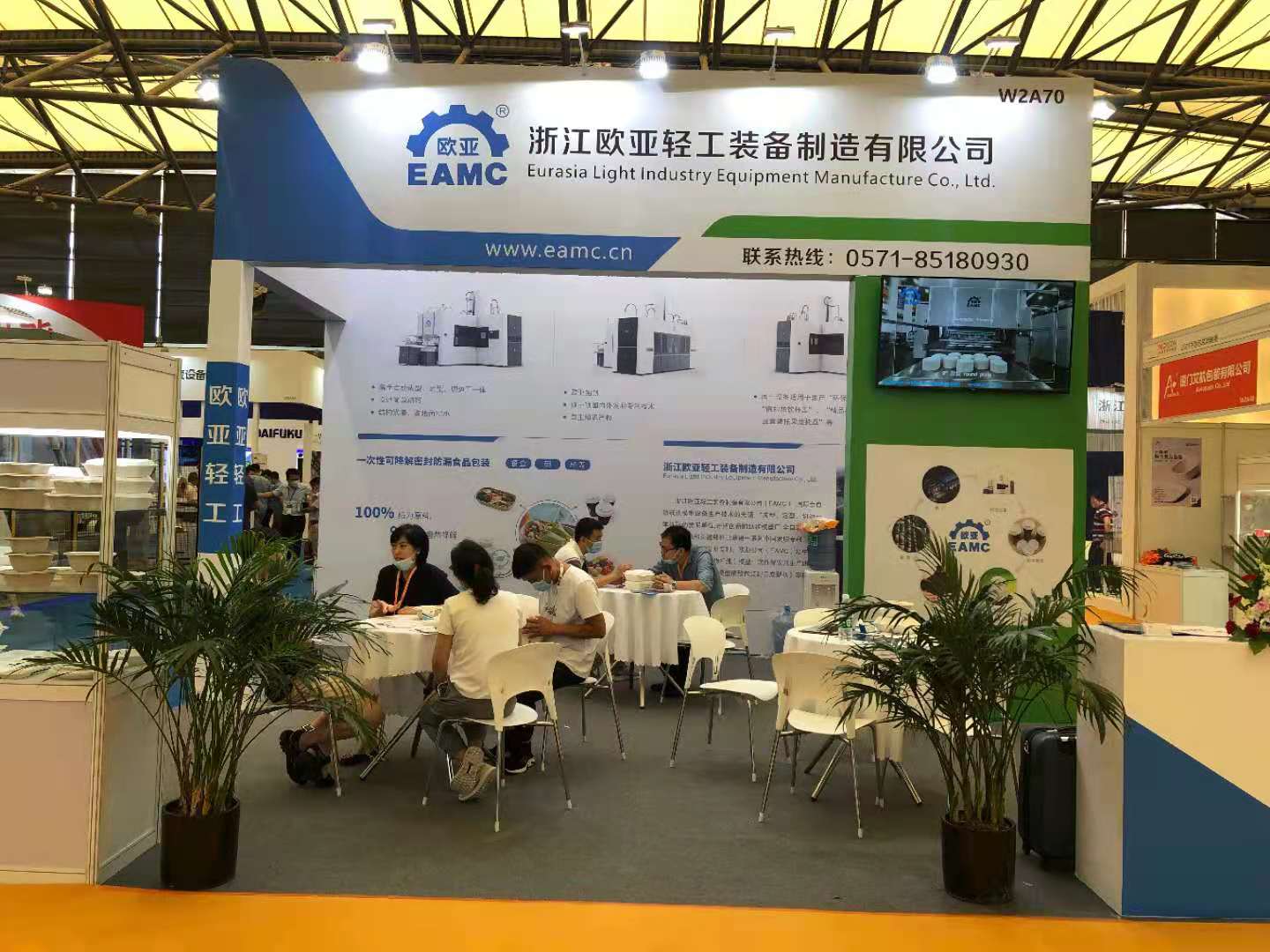

EAMC participated in the exhibition, at which it exhibited the EAMC "molding, shaping, edge cutting, punching" one-in-one machine and EAMC molded pulp cup lid production technology.

EAMC sets 20 years of development and research experience and production experience of the new technology of "plant fiber molding", and creates the original EAMC "molding, shaping, edge cutting, punching" one-in-one machine and pulp molding cup lid production technology. The output per machine is 1.2-2.5 tons per day. EAMC "molding, shaping, edge cutting, punching" all-in-one machine features a multi-functional equipment.

The replacement of mold can be formed: automatic molded pulp tableware production line, automatic molded pulpcup lid production line, moldedpulp quality industrial packaging production line, automatic molded pulp cake support production line, can also form automatic moldedpulp egg box production line and other production line and product factory for different purposes.

EAMC pioneered plant fiber molded cuplid with inverted buckle: "A plant fiber moldedcup lid with an inner convex ring" has been patented, and has obtained the same patent certificate, and the international patent has also been declared.

"A plant fiber moldedcup lid with the inner convex ring" is the appropriate position of the inside of thecup lid, act as the "buckle", its effect is to buckle the cup lid on the "ring rim" of the cup, play the "inverted buckle" role. The inner convex ring can jam the paper cup ring mouth edge to prevent the ring mouth edge of the cup from slipping out of the "curved groove" of the cup lid. It plays two roles: 1, let the cup lid get in close contact with the "ring mouth edge" of the paper cup; 2, the cup lid does not easily fall off from the cup when the cup is dumped.

In the process of hot pressing the wet blank of the cup lid into a dry and shaped cuplid product, the inner convex ring is directly squeezed in the hot pressure forming process, without a second processing. The outside of the EAMCcup lid is kept smooth, with beautiful structure, good sealing effect, good anti-stripping effect, convenient production forming, and significantly reduced production cost.

Under the general trend of global plastic ban, the rise of plant fiber molding industry is the inevitable result of this historic opportunity.

"Plant fiber molding" is the use of renewable plant resources such as wheat grass (or reeds), bagasse and other plant fiber cardboard, through molding the production of a variety of fiber daily necessities, molded fiber tableware, molded fiber packaging, molded fiber tray, plant fiber industrial products shock pad and packaging tray, non-plane plant fiber decoration decorative wall board and non-plane plant fiber three-dimensional products.

shouldering the important mission of solving the problem of white pollution, EAMC After decades of development, production, and application, it has more than 10 national invention patents, 1 US invention patent, and 1 EU invention patent.

Under the global warming environment, global advocate carbon neutral, Advanced EAMC pulp molding equipment technology provides automatic pulp molding tableware production line, automatic pulp molding cup lid production line, pulp mold quality industrial packaging production line, and automatic molded pulp cake support production line for the same internal and external large enterprises. Using degradable plant raw materials: such as various pulp boards, reed pulp, straw pulp, sugarcane pulp, bamboo pulp, straw pulp, wood pulp, etc., the production of each packaging products, perfect to achieve the packaging demand, and completely degradable, no need to worry about the environment pollution.

High quality EAMC fully automatic pulp molding equipment is developed for high-end users.